Why Didn’t I Think

Of That?

The Development Of A New Laborsaving Installation Device

By Jim Jackson

David West, a Cottage Grove, Minn., electrician was frustrated. Back in 1995, while doing an alarm install in a large department store, he found himself quickly losing patience with the tedious process of stringing cable from zone to zone. Up to that time, West’s low-voltage experience had primarily been in the residential environment, and as a result, he wasn’t yet acclimated to the difficulties encountered in these larger commercial structures.

Of course, the difficult situation West encountered – installing cable across suspended ceilings and in limited access areas – is a common one for any installer who works in these environments. Typical methods, such as using fiberglass poles to push or pull the cables, tying a weight to the cable and throwing it in the proposed direction, or coiling the cable and tossing it under or over obstructions repeatedly, all bring frustration in their wake. West decided there had to be a better way.

“The solution came to me while I was working on this job the department store project],” said West. “I envisioned hat a solution should do and how it should look.”

Although intrigued by the prospect, West felt certain that such a tool must already exist, so he asked his fellow installers if they knew of one. When he received only negative responses, he went on to query several project managers, both inside his company and out. They weren’t aware of one either. After a little more research, he felt reasonably certain that the product he had in mind had yet to be developed. At that point, West decided he had a very marketable idea and should explore it further.

“The first step I took (in product development) was to interview people involved in the trades, from foremen and master electricians, to project managers and industry business owners, as well as anyone else who could relate to such a device,” said West. “And they were all positive about what I wanted to do.”

A few years passed during which time West worked on the project sporadically, toying with the design and a prototype. As with most inventors, he faced the frustrating issue of raising capital for the project. Fortunately, he was eventually able to begin a patent search and was thrilled when he found that no patented design existed for the device he envisioned. His idea now stood on the brink of becoming a reality.

The Prototype

The product West had in mind was a “gun” of sorts, which would propel a small projectile attached to a pull line, thus allowing the cable to be extended over great distances. The device would also include a laser sight to aid in directing the projectile to its destination.

West considered several possibilities for a suitable launching device, the key component of the prototype, but found the best fit from an unlikely source: the wild and wicked game of paintball. In this sport, where participants

set out to capture their opposing team’s flag while protecting their own, a special CO2 powered gun is used to propel colored liquid-filled gelatin capsules at opponents, thus eliminating them from the game.

After some changes to the valve system of this unusual plaything to adjust its velocity, West had his launching device. He added to this a makeshift projectile, a laser sighting device, a string supply system and an improvised clamp to bring it all together.

West conducted a lengthy period of trial and error refinement in the field, where he also brought in other installers and professionals for their feedback. He even worked with a gunsmith for some pointers on working with projectiles. Once he had achieved the level of performance he felt was demanded for such a product, he moved on to a major hurdle: finding a manufacturer. West said it was difficult finding a manufacturer that was not only able to see the potential of the product but that was also able to come in at a fixed price point to ensure that the final product would be affordable by the time it reached the end user. Ultimately, he found a manufacturer with an established and respected reputation, who could assure a quality process.

LaserLine™

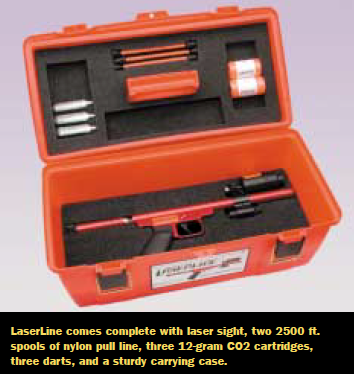

After several years of hard work, West will see the formal introduction of his product, LaserLine, to the industry at large later this month. This lightweight CO2 powered device propels varying lengths of nylon pull line using a small projectile. The projectile is equipped with a soft rubber tip and a quick release attachment

system that doesn’t require tying or cutting, and the attached laser-sighting device can be used by the installer as a directional guide. The LaserLine is constructed of quality-machined aluminum and has an anodized finish.

Of course, with a tool this powerful, safety is certainly an issue. The product prominently displays safety warnings, most important of which is that all those in the work area wear eye protection. A safety feature is included within LaserLine’s barrel that prevents misfiring when the projectile is loaded as well. The velocity of the projectile is such that it would not harm any ductwork or other equipment commonly found in the ceiling or a similar work area.

Ultimately, the LaserLine is designed to accurately span a much greater distance than possible with traditional makeshift methods, thereby making it easier to route cables in an orderly fashion. Once the paths (routes) have been established, supports can be placed (typically at 5-foot intervals) and an efficient placement plan can be implemented, minimizing the repeated efforts of simply finding the right path.

According to West, initial reports from installers and contractors who have used LaserLine give it a wholehearted thumbs-up. Many have commented not only on the reduced effort required and the product’s ability to span heavy and hard-to-move objects, but also on how straight and accurately the line is propelled. With the point-to-point routes determined and the pull-line supports in place, productivity is improved and labor intensity is decreased.

West is eager to see the product move into use on a widespread basis and sincerely thinks it will have a significant impact on the installation of low-voltage cabling. Ultimately, hard work and perseverance have brought his original idea into fruition. West’s experiences emphasize to all of us the principle that good ideas alone are not enough; they require a lot of hard work and persistence to make them a reality.

To find out more about LaserLine, visit an informational web site at www.thelaserline.com. Or call 612-790-7729 or email westindust@aol.com